A Journey through the Assembly Line

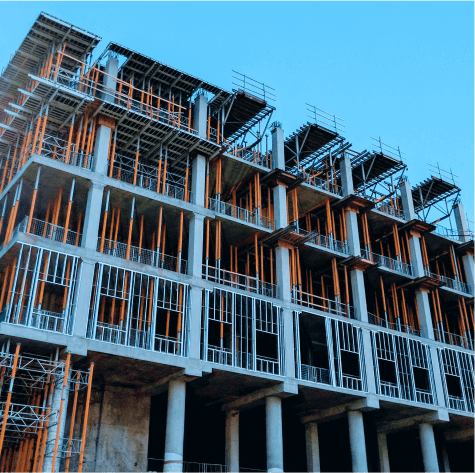

Embark on a captivating journey through the assembly line, where the rhythmic symphony of machinery orchestrates the creation of products with meticulous precision. As you step onto the factory floor, a symphony of clanks, whirs, and hums envelops your senses, setting the tempo for an immersive exploration of industrial craftsmanship. The assembly line unfolds like a well-choreographed dance, with each station playing a crucial role in the ballet of production. Conveyor belts carry the raw materials, whispering tales of their origin, while automated arms deftly manipulate components, transforming them into intricate pieces of a larger puzzle. The air is charged with the scent of metal and the faint aroma of lubricants, creating an industrial bouquet that lingers as you progress through the process. Workers, akin to skilled artisans, monitor the assembly line with a watchful eye, ensuring the seamless integration of parts. Their hands move with practiced efficiency, a testament to years of expertise in the dance of assembly. The ambiance is alive with a sense of purpose, as each worker becomes a guardian of quality, contributing to the creation of something greater than the sum of its parts.

Leave a Reply

You must be logged in to post a comment.