Revolutionizing Production Today’s Factories

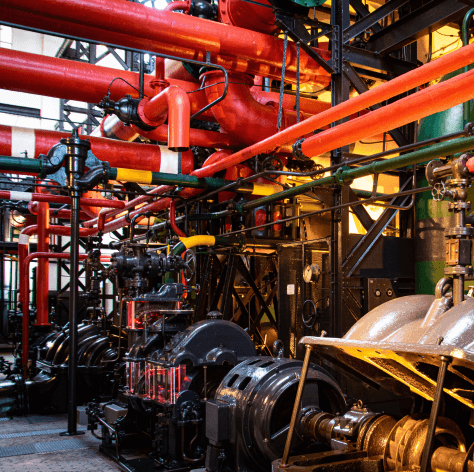

Revolutionizing production in today's factories involves a comprehensive transformation that transcends traditional manufacturing paradigms. This evolution encompasses a profound shift in both processes and mindset, fostering a dynamic environment where innovation and efficiency converge to redefine the very essence of quality in manufacturing. At the core of this revolution is the seamless integration of cutting-edge technologies, such as advanced robotics, artificial intelligence, and the Internet of Things (IoT). These technologies converge to create a harmonious symphony of interconnected systems, orchestrating production with unprecedented precision and agility. Automation, driven by intelligent algorithms and real-time data analysis, eliminates bottlenecks and inefficiencies, paving the way for a leaner, more responsive manufacturing ecosystem.

Leave a Reply

You must be logged in to post a comment.